gantry machining center DM-1613

Contact:Mr. Li

Phone:+86 15588213763

Address:No. 9 Beixin West Road, Jinghe Street, Zaozhuang

Click:

一、Main performance of machine tool

Machine Tool Name: gantry machining center

This machine tool is a high rigidity, high-precision gantry machining center, especially suitable for processing various steel and aluminum parts. Smooth movement and precise positioning. Based on the characteristics of machine tool processing and the requirements of modern high-precision and high-efficiency processing, this machine tool integrates machine, electrical, and hydraulic technologies and is designed and manufactured with new technologies in modern machine tool development. It can perform rough and fine machining, with strong and efficient continuous machining capabilities during rough machining, and excellent surface machining quality and accuracy during fine machining. The overall structure of the machine tool adopts the finite element method structural design with international advanced concepts in cooperation with Southeast University, which has good load-bearing capacity, scientific stress distribution, and high stability. The overall stiffness and strength design are based on consistent design principles to ensure sufficient overload margin and a high safety factor, making the machine tool have strong overload capacity and impact resistance, and can work continuously for three shifts without stopping.

The machine tool has a high rigid structural design, reliable precision stability and retention, and complete matching. The parts are designed in a modular way, with high standardization. It has good interchangeability and stable quality. The machine tool is advanced in design, reliable in performance, simple in operation, and convenient in maintenance. At the same time, this machine tool is an introduction and absorption of advanced equipment and process technology from Europe by our company. The entire machine has a high rigidity frame structure design, which not only has the ability to perform strong cutting, but also meets the processing requirements of precision parts.

二、Main specifications and technical parameters

|

1.Control System |

|

|

|

(1) Software: AICC2/R660/Nano Smooth/Arc Turning Point/Mirror Processing |

FANUC 0I MF PLUS 3 |

|

|

(2) Monitor: Display in both Chinese and English |

10.4″ 10.4 "color screen |

|

|

(3) CF card interface, handheld portable operating system |

|

|

|

2. Stroke |

|

|

|

(1) x-axis |

1600 |

mm |

|

(2) y-axis |

1300 |

mm |

|

(3) z-axis |

700 |

mm |

|

(4) Spindle nose to table |

100-800 |

mm |

|

3. workbenches |

|

|

|

(1) Table size |

1700X1050 |

mm |

|

(2) Max. loading capacity |

2 |

T |

|

(3)Door width |

1235 |

mm |

|

(4) Size of T-slot |

22x140x7 |

mm |

|

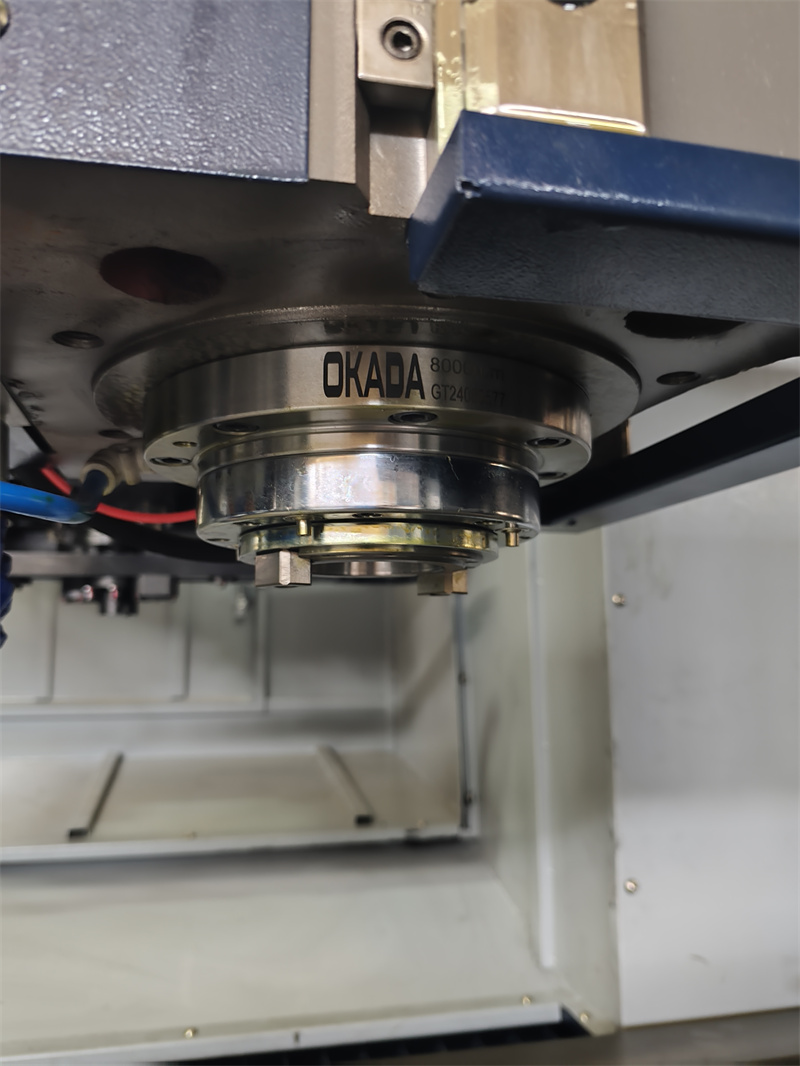

4.SPINDLE ——Taiwan Grid/OKADA |

|

|

|

(1) Spindle speed |

6000 |

rpm |

|

(2) Spindle taper |

BT50 |

|

|

(3) Spindle motor |

15/18.5 |

KW |

|

(4) Spindle torque |

236 |

N.m |

|

5. SLIDE WAY |

|

|

|

(1) x轴 (x-axis) (2导轨 guide rails) |

45x2 roller P grade |

mm |

|

(2) y-axis guide rails |

45x2 roller P grade |

mm |

|

(3) z-axis |

45*2+35*2 |

mm |

|

6. Driving screw |

|

|

|

(1) Ball screw accuracy |

C3级 |

|

|

(2) Ball screw diameter x.y.z |

50/50/50 |

mm |

|

(3) Three-axis lead |

10/12 |

mm |

|

(4)Motor connection |

Direct connection |

|

|

(5)Number of bearings at both ends |

6/6/6 |

|

|

7. Three-axis motor |

|

|

|

(1) x zaxis motor |

Bis30/2000 |

N.m |

|

(2) y zaxis motor |

Bis30/2000 |

N.m |

|

(3) z zaxis motor Nitrogen-containing equilibrium |

Bis40/2000 |

N.m |

|

8. FEED RATE |

|

|

|

(1)x axis rapid feed rate |

20000 |

mm/min |

|

(2) Y axis rapid feed rate |

20000 |

mm/min |

|

(3) Z axis rapid feed rate |

20000 |

mm/min |

|

(4)Three-axis cutting feed rate |

0-10000 |

mm/min |

|

9. ( tool ) |

|

|

|

(1) Max. tool length |

300 |

mm |

|

(2)Max. tool dia |

200 |

mm |

|

(3) Max. tool weight |

15 |

kg |

|

(4) Tool specification |

BT50 |

|

|

(5) Tool change time |

2 |

秒 |

|

(6) Number of cutting tools |

24 |

把 |

|

Factory precision (full stroke VDI/DGQ3441) |

|

|

|

(1) Positioning |

0.010/1000 |

mm |

|

(2) Repeat positioning |

0.006/1000 |

mm |

|

(3) Least input increment |

0.001 |

mm |

|

10. Other |

|

|

|

(1) Power Capacity |

30 |

KVA |

|

(2) Net weight |

13.5 |

t |

|

(3)Packing dimensions Packing dimensions(Length x Width x Height)) |

4700x3200x3600 |

mm |

三、Machine tool characteristics

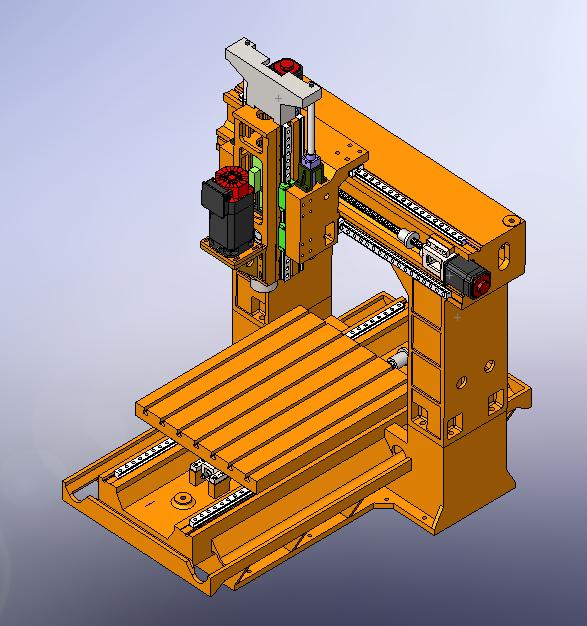

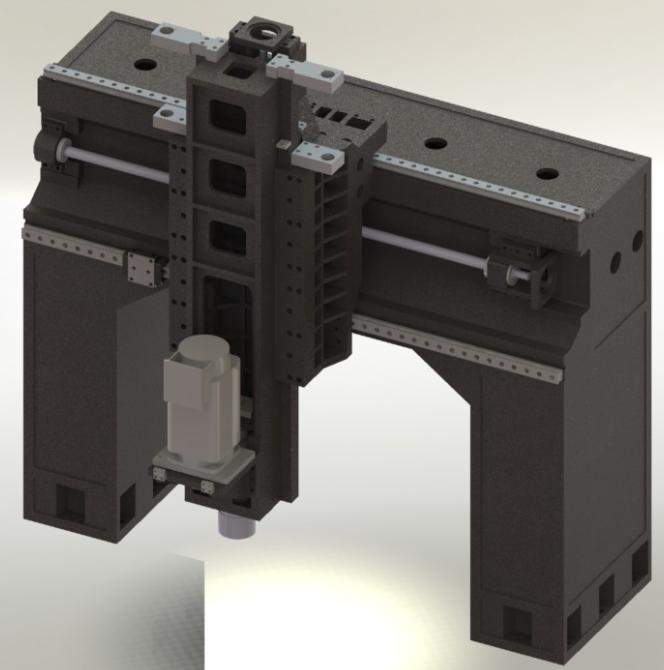

1.High rigidity structure

The bed is made of precision high-quality resin sand cast iron. Secondary aging treatment through thermal aging and vibration aging. The overall structure of the machine tool consists of a closed rigid frame structure consisting of a bed body, double columns, and fixed crossbeams. The worktable moves longitudinally along the bed guide rail (X-axis), and a vertical high-power multifunctional slide milling (boring) head is configured on the fixed crossbeam. The milling and boring head slide moves laterally along the crossbeam guide rail (Y-axis) and the slide boring and milling head moves up and down (Z-axis)

The main basic components of the machine tool, such as the bed body, worktable, column crossbeam, transverse slide plate, milling head slider, etc., are all made of high-strength cast iron and molded with resin sand, which has good shock absorption, thermal stability, high structural strength and rigidity of the whole machine. The Y-direction two guide rail design is optimized by finite element analysis method to achieve maximum rigidity and stability.

The machine tool door frame is a one-piece cast structure with excellent rigidity.

The wide base and the design of two X-directional guide rails make the machine tool as stable as a rock, with excellent rigidity.

The vertical sliding pillow milling head adopts a ball screw direct transmission design mechanism and a high-power AC servo motor, maximum torque 236N/M, ultra-high stability, maximum speed 6000 rpm, slide pillow boring and milling.The head adopts a mechanical spindle unit structure produced in Taiwan, which is easy to install, disassemble, maintain and repair, and comes withThere is an automatic marathon knife device with gas-liquid pressure compound release and disc spring tension.The rectangular slider milling head adopts a direct connection method, and the spindle servo motor is equipped with an encoder, which can achieve spindle orientation and spindle control.Rigid tapping function of the shaft.

Standard nitrogen balance greatly reduces spindle thermal extension, thereby improving machining quality.

2.High precision and high specification screw

The three-axis machine tool comes standard with Japanese THK screw, and can also be equipped with hollow screw, greatly ensuring the accuracy of the machine tool.

The diameter of the three-axis screw of the machine tool is 50/50/50mm, and the lead is 12mm.

The three-axis servo and screw are directly connected, greatly controlling the conduction gap.

3.High precision heavy-duty guide rail

Two 45mm heavy-duty roller guides are used in the X direction to ensure heavy loading.

Two 45mm heavy-duty roller guides are used in the Y direction to ensure the stability of Z-axis motion.

4.Precision spindle

The spindle adopts Taiwan's BT50-160 spindle, ensuring the rigidity of heavy cutting of the spindle.

5. Comprehensive testing

The machine tool is tested using a laser interferometer and ball bar from the British company RENISHAW to ensure the accuracy of linear motion and dynamic response performance of the machine tool. The spindle and spindle motor are dynamically balanced by a spindle vibration meter to ensure the smoothness of high-speed motion.

6.Beautiful, high-end, and safe electrical design

The electrical design fully complies with CE standards. The use of imported cables effectively reduces the impact of electrical interference, while adopting European circuit design and manufacturing standards for stable and easy to maintain electrical appliances.

7.Tool cooling system

The tool cooling system adopts an external circulation method, and the coolant flows into the chain plate elevator at one end of the bed through the spiral chip discharge grooves on both sides of the bed. After filtration and separation, the coolant flows into the coolant tank on the elevator, and then is delivered to the cooling nozzle at the spindle part through the coolant electric pump.

8.Smooth chip removal system

Spiral chip conveyors are installed on both sides of the machine bed, which can concentrate the processed iron chips and transport them to the chain plate lifting device at the front end of the machine bed. The lifting device is equipped with a cutting fluid water tank, which has a high head coolant pump. The high head water pump transports the purified cutting fluid to the spindle end, which has multiple cooling nozzles that spray cutting fluid onto the tool to cool it. The chips are collected by the hoist and transported to the recycling truck.

9.Lubrication of machine tool guide rails

The lubrication of each axis guide rail adopts a central integrated self timed quantitative lubrication system, which is automatic lubrication with safety protection against pressure loss and oil shortage.

10.Protection form

The X-axis guide rail of the machine tool is protected by a stainless steel telescopic protective cover.

The Y-axis guide rail of the machine tool is protected by a telescopic accordion guard.

Install maintenance ladders and protective railings on the gantry frame.

X. The Y and Z axes are equipped with drag chain protection devices.

11.Numerical Control System

The CNC system adopts the Japanese FANUC 0I MF PLUS 3 model.

12.Electronic control auxiliary device

Fully enclosed constant temperature electrical cabinet, standard protection, sealed dust-proof, and equipped with lighting inside the electrical box.

The main operation station can conveniently perform various operations and controls, and is equipped with an electronic handwheel. The machine tool is equipped with servo system overload automatic protection and alarm device, as well as mechanical part power-off protection device.

Set software limits for each motion axis of the machine tool.

13.other

Machine tool power demand: 30KVA, the machine tool has leakage protection and power-off protection.

(1)Three color indicator light for machine tool working status.

(2)The machine tool noise meets national standards.

(3)Three phase AC power supply: 380V ± 10%, - 15%; 50Hz ± 1Hz.

(4)Environmental temperature: 10-30 ° C.

(5)Relative humidity: ≤ 80%.

(6)Gas source pressure: 0.6~0.8 MPA

四、Machine Tool Configuration Table

1.Main accessories

|

Serial |

configuration |

producers |

country of origin |

specifications |

|

1. |

control system |

FANUC |

Japan |

0I-MF |

|

2. |

servo system |

FANUC |

Japan |

0I-MF |

|

3. |

Spindle Motor |

FANUC |

Japan |

0I-MF |

|

4. |

Three axis motor |

FANUC |

Japan |

0I-MF |

|

5. |

main shaft |

Grid/OKADA |

Taiwan |

BT50 |

|

6. |

Three axis ball |

THK |

Japan |

C3 |

|

7. |

bearing |

FAG |

Germany |

|

|

8. |

Roller track

|

THK |

Japan |

|

|

9. |

coupling |

Reddy |

China |

|

|

10. |

Loosening tool devicesystem |

Zhenshang |

Taiwan |

|

|

11. |

air-conditioning |

Riko |

joint venture |

300W |

|

12. |

Three point |

SMC |

Japan |

|

|

13. |

Electrical |

schneider |

France |

|

|

14. |

Hand pulse |

Dongche |

Japan |

|

|

15. |

Centralized lubrication pump

|

BAOTA |

China |

|

|

16. |

Guide rail cover |

Zhenfei |

Shanghai |

|

|

17. |

Chip conveyor |

OEM |

|

|

|

18. |

Nitrogen balance |

Tie Ning |

Taiwan |

|

|

Note: Due to production needs, the manufacturer reserves the right to |

||||

2.Standard configuration

|

1 |

Machine tool shell protective cover |

10 |

Warning light (with buzzer) |

|

2 |

Automatic Lubrication System |

11 |

Foot cushion block |

|

3 |

Workpiece cooling system |

12 |

Spindle nose labyrinth dustproof blowing |

|

4 |

Work light |

13 |

Handheld chip blowing air gun |

|

5 |

Electrical box air conditioning |

14 |

Rigid tapping |

|

6 |

Spindle air curtain dust prevention system |

15 |

Door opening protection device (protective door) |

|

7 |

Nitrogen balance bar |

|

|

|

8 |

Precision oil cooler |

|

|

|

9 |

Spiral+chain plate type chip conveyor |

|

|

五、Machine tool manufacturing standards

|

1 |

General technical specifications for metal cutting machine tools. |

GB9061-2006 |

|

2 |

Mechanical safety, mechanical electrical equipment Part 1: General technical specifications. |

GB5226.1-2002 |

|

3 |

General technical specifications for hydraulic systems of metal cutting machine tools. |

JB10051/T-1999 |

|

4 |

General technical specifications for safety protection of metal cutting machine tools. |

GB15760-2004 |

|

5 |

Technical specifications for CNC gantry boring and milling machines. |

JB/T6600-2006 |

|

6 |

Precision of CNC gantry boring and milling machine. |

GB/T19362.1-2003 |

|

7 |

Technical conditions for machine tool packaging. |

JB/T8356.1-1996 |

|

8 |

The electrical equipment complies with IEC standards and adopts international advanced standards. |

|

|

9 |

The measurement of equipment instruments and meters adopts ISO international standard units of measurement. |

|

六、List of Random Tools and Materials

|

Serial number |

name |

Specifications or markings |

quantity |

|

1. |

Glass glue+glue gun |

white |

1bottle |

|

2. |

Electronic handwheel |

|

1 piece |

|

3. |

Card reader+card holder |

|

1 piece |

|

4. |

Work gloves |

|

1 pack |

|

5. |

cleaning cloth |

|

1 pack |

|

6. |

screw |

|

1 pack |

|

7. |

base |

|

1 set |

|

8. |

certificate of compliance |

|

1 copy |

|

9. |

Mechanical instructions |

|

1 copy |

|

10. |

Electrical Manual for Machine Tool Operation and Maintenance |

|

1 copy |

|

11. |

Electrical Schematic diagram |

|

1 copy |

|

12. |

Fanuc Product Warranty Certificate |

|

1 copy |

|

13. |

User Manual for Precision Oil Refrigeration Machine |

|

1 copy |