CNC Vertical (Milling) Machining Center VMC1160

Contact:Mr. Li

Phone:+86 15588213763

Address:No. 9 Beixin West Road, Jinghe Street, Zaozhuang

Click:

1.Function and feature description

1.1Machine tool usage

VMC1160 vertical machining center is mainly suitable for parts processing in industries such as aviation, aerospace, automotive, military, energy, information, and molds. Targeting the processing of small and complex parts of black and non-ferrous metals, it has the characteristics of high precision, high speed, high flexibility, and environmental friendliness. Its performance and accuracy indicators fully comply with national standards. Through modular design, the product can be serialized and customized according to market demand, and its good performance price ratio is the best choice for domestic and foreign customers.

The design of the machine tool complies with ISO international standards, and all parts, components, and various instruments are measured using the International System of Units (SI) standard.

1.2Product Introduction

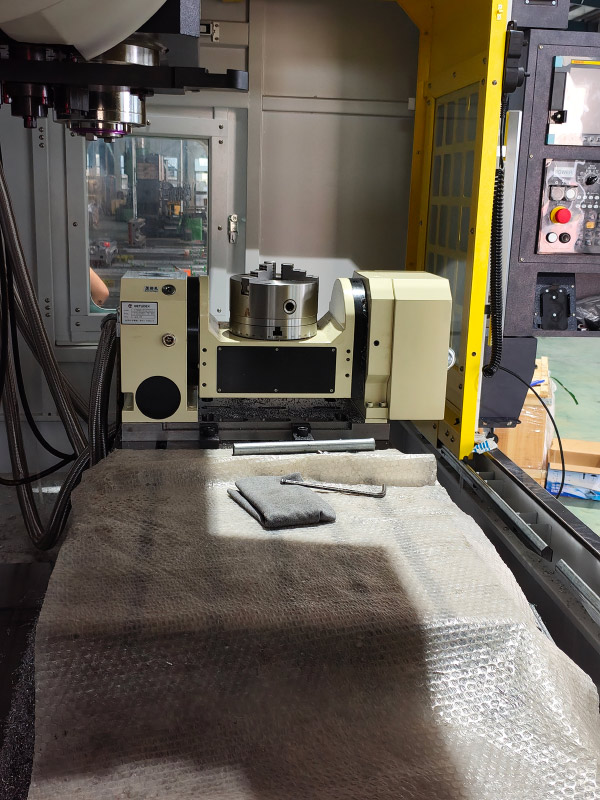

This product is a semi closed loop vertical machining center with X, Y, and Z three-axis servo direct control. All three axes are steel column rolling linear guides, with large guide rail loads, wide spans, and high precision. The X, Y, and Z axes all use 45mm wide heavy-duty linear guides, and the X and Z axes are all equipped with 6 sliders. The structure and external dimensions are compact and reasonable, and the spindle is driven by a servo motor through a synchronous belt. It can achieve one-time clamping of various complex parts such as disks, plates, shells, camshafts, molds, etc. It can complete various processes such as drilling, milling, boring, expanding, reaming, and rigid tapping, suitable for the production of multiple varieties and small to medium batch products, and can meet the processing of complex and high-precision parts. Can be equipped with a fourth and fifth rotation axis to meet the processing requirements of special parts.

1.3Main structural features

The main foundation components such as the base, slide, worktable, column, and spindle box are all cast with high-strength HT300 cast iron material and resin sand technology. The base is a box type structure, and the compact and reasonable symmetrical reinforcement structure ensures the high rigidity and bending and shock absorption performance of the foundation components; The A-type bridge span column and internal grid like reinforcement effectively ensure the rigidity and accuracy during Z-axis strong cutting; The basic components are molded with resin sand and undergo aging treatment, providing stability for the long-term performance of the machine tool.

X. The Y and Z guide rails are both heavy-duty linear roller guides from original Taiwan HIWIN or PMI companies, with low friction coefficient, high worktable sensitivity, low high-speed vibration, no crawling at low speeds, high positioning accuracy, and excellent servo drive performance; At the same time, it has a high load-bearing capacity and good cutting anti vibration performance, which can improve the performance characteristics of the machine tool, enhance the accuracy and stability of the machine tool, and extend its service life.

X. The Y and Z directions are fed using high-precision and high-strength internal circulation double nut preloaded large lead ball screws with high feed speed; The drive motor is directly connected to the screw through an elastic coupling, and the feed servo motor directly transmits power to the high-precision ball screw without backlash, ensuring the positioning accuracy and synchronization of the machine tool;

The Z-axis motor is equipped with an automatic brake function. In the event of a power outage, the automatic brake will hold the motor shaft tightly, preventing it from rotating.

The spindle assembly is produced by a professional factory in Taiwan, which has high speed, high precision, high rigidity, and strong axial and radial bearing capacity. The spindle gripping tool relies on the butterfly spring on the spindle to exert tension through a four petal claw type pulling mechanism on the pull pin of the tool handle, and is achieved by the tight fit between the tool and the spindle taper hole.

The spindle adopts a central blowing structure, which quickly cleans the inner cone of the spindle with central high-pressure gas when the spindle loosens, ensuring the accuracy and service life of tool clamping.

The machine tool has a spindle orientation function.

High precision pitch compensation, each transmission shaft adopts high-precision laser for detection and optimization compensation, making the positioning accuracy of each axis more accurate and more suitable for processing high-precision parts. At the same time, advanced ball bar instruments are used to optimize analysis and processing, ensuring the accuracy of the machine tool in circular and curved surface machining.

1.4 Machine tool protection

X. The Y and Z direction guide rails and lead screws are equipped with protective devices to ensure the cleanliness of the lead screws and guide rails, and to ensure the transmission and motion accuracy and service life of the machine tool;

The machine tool adopts a fully enclosed and environmentally friendly protective structure design, which is easy to operate, safe and reliable, beautiful and generous, effectively preventing iron filings and coolant splashing, allowing operators to work in a safe and comfortable environment.

1.5magazine

Using 24 disc type robotic arm knife magazines (optional) or 20 conical hats (optional) produced by professional manufacturers in Taiwan, the tool change is accurate, the time is short, and the efficiency is high. After millions of operation tests, it meets the reliability requirements; Equipped with a damping structure, it can reduce the impact during movement and ensure the service life of the tool magazine; Pneumatic drive, easy to use, shortest path for tool change;

Maximum tool diameter (adjacent space): φ80/φ150mm

Maximum tool length: 300mm

Maximum tool weight: 8kg

1.6lubrication system

The three coordinate bearings are lubricated with grease.

The ball screw pairs are all lubricated with automatic thin oil. Automatic intermittent lubrication of various lubrication points on the machine tool at regular and quantitative intervals, and the lubrication time can be adjusted according to the working conditions.

The Y and Z coordinate guides are linear rolling guides that use automatic thin oil lubrication. The lubricating oil is divided by a splitter and connected to each slider for lubrication.

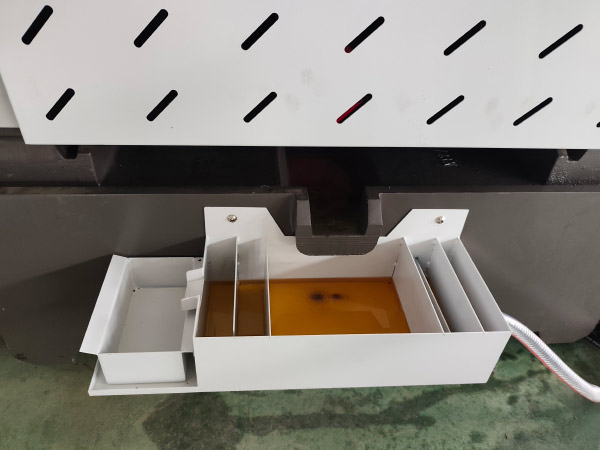

1.7Oil water separation system

By using an oil-water separation device, most of the collected lubricating oil can be separated from the coolant, preventing rapid deterioration of the coolant and promoting environmental protection;

1.8 Cooling and chip removal system

Water tank capacity: 140L

Cooling pump power: 440W

Cooling pump flow rate: 67L/min

Rated head: 16m

1.9 Pneumatic system

Mainly used for spindle loosening and tool clamping; Blowing air from the center of the spindle; Sealing and blowing air at the front end of the spindle, as well as the upper and lower parts of the tool magazine and cup.

1.10 Chip removal system (optional)

Spiral or chain type chip conveyors can be selected, and the iron chips processed on the workbench are transported to the trolley through spiral or chain type chip conveyors.

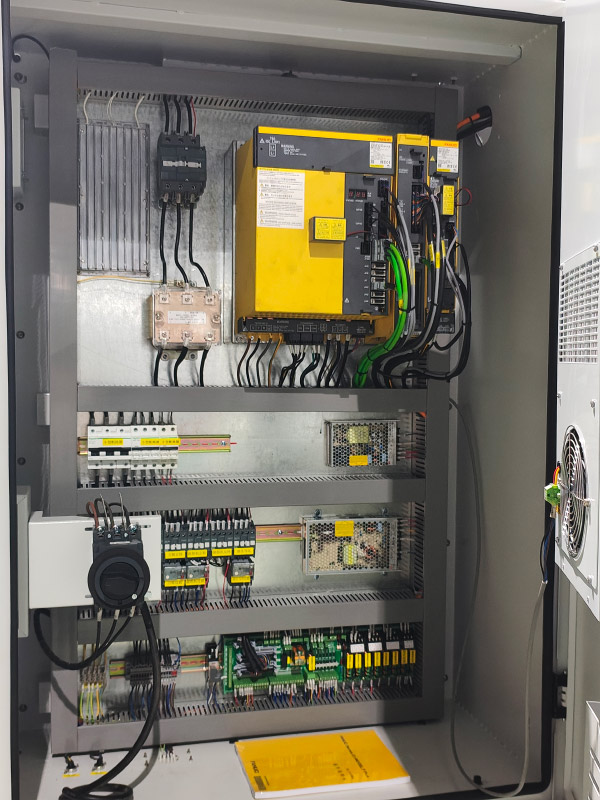

1.11 Cooling device for electrical cabinet

The CNC cabinet of the machine tool is equipped with a dust-proof and dehumidifying air conditioning device, allowing the CNC system to operate in a dust-proof and temperature controlled environment, ensuring its long-term reliability.

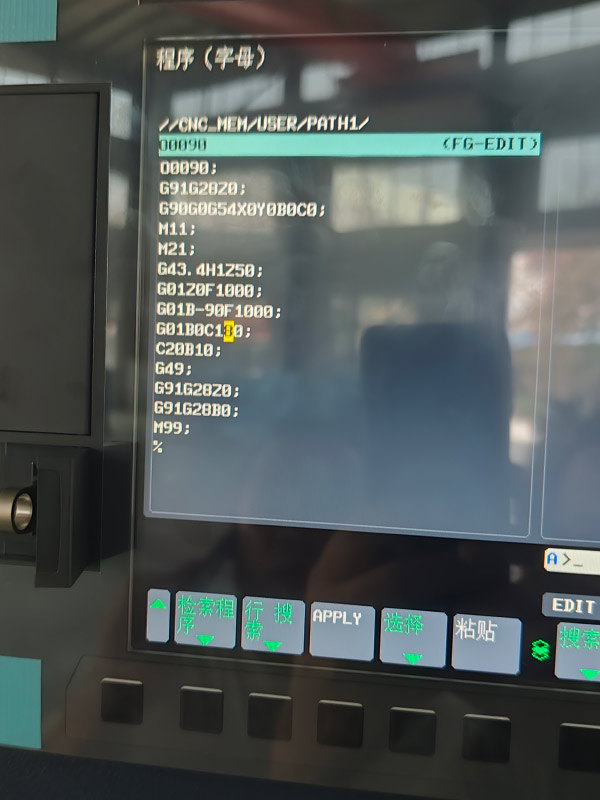

1.12 Numerical Control System

Foreign systems: SIEMENS 808D or 828D、 FANUC 0i MF-PLUS、 Mitsubishi M80

Domestic systems include KND, HNC, GSK, and SYNTEC(according to customer requirements)

1.13 Working conditions of machine tools

Ø Power supply: AC380V ± 10%, 50HZ ± 1% three-phase AC.

Ø Gas source: 0.6-0.8Mpa

Ø The temperature range of the machine tool workshop environment is 10-35 ℃, the relative humidity is 40-75%, the atmospheric pressure is 86-106Kpa, the dust concentration in the air should not exceed 10mg/m3, and it should not contain acids, salts, or corrosive gases. The machine tool is installed in a workshop far away from the earthquake source, heat source, and heat flow, with a vibration of less than 0.5G (G is the acceleration due to gravity).

Ø The machine tool must be safely grounded using a separate cable, preferably with a 1.5m copper rod driven underground, and the grounding resistance should be less than 4 ohms. (Any subsequent issues caused by ungrounded grounding are not related to our company)

2.Main specifications and technical parameters

|

Product model |

VMC1160 |

unit |

|||

|

workbenches |

Workbench size |

1200×600 |

mm |

||

|

Maximum allowable load |

800 |

Kg |

|||

|

T-shaped slot size |

18×5 |

mm×个 |

|||

|

machine range |

Maximum travel of workbench - X-axis |

1100 |

mm |

||

|

Maximum travel of sliding saddle - Y-axis |

600 |

mm |

|||

|

Maximum spindle travel - Z-axis |

600 |

mm |

|||

|

Spindle end face to Worktable distance |

maximum |

720 |

mm |

||

|

minimum |

120 |

mm |

|||

|

Spindle |

Conical hole (7:24) |

BT40 |

|

||

|

Revolution range |

50~8000 |

r/min |

|||

|

Spindle motor power |

11/15 |

kW |

|||

|

Feed rate |

Range of cutting feed rate |

1~10000 |

mm/min |

||

|

Quick movement |

x-axis

|

24 |

m/min |

||

|

y-axis |

24 |

||||

|

z-axis |

24 |

||||

|

Machine tool positioning accuracy |

X Y Z |

Execution standards: JB/T8771.4-1998 |

±0.008 |

mm |

|

|

repeat positioning accuracy |

X Y Z |

Execution standards: JB/T8771.4-1998 |

±0.003 |

mm |

|

|

Weight |

7000 |

Kg |

|||

|

Total electrical capacity |

20 |

KVA |

|||

|

Machine tool outline dimensions |

3400×2480×2960 |

mm |

|||

3.Main purchased components

|

Product Name |

Origin and manufacturer name |

|

Spindle assembly |

Volis/ROYAL/KENTORN

|

|

Screw bearings |

NSK/FAG |

|

linear guide rail |

HIWIN/PMI |

|

Ball screw |

HIWIN/PMI |

|

Cooling pump |

Domestic brand |

|

Oil separator |

Japanese HERG (Foshan)/BAOTN |

|

Lubrication pump |

Japanese HERG (Foshan)/Golden Armor |

|

Main electrical components |

Schneider/Delixi |

|

Main pneumatic system |

AirTAC/SMC |

|

Knife cylinder |

Taiwan spindle assembly belt |

4. Acceptance criteria and methods

|

Standard Name |

Standard number |

|

Acceptance criteria for geometric accuracy of machine tools |

JB/T8771.2-1998 |

|

Acceptance criteria for machine tool motion accuracy |

JB/T8771.4-1998 |

|

Acceptance criteria for machine tool working accuracy |

JB/T8771.7-1998 |

The product acceptance is conducted in two stages. The first pre acceptance will be conducted by Party B, and the second final acceptance will be conducted after installation and commissioning by Party A. Acceptance shall be carried out in accordance with the product contract and technical agreement. According to the technical standards implemented by the product, inspect the appearance quality, function, and geometric accuracy of the machine tool.

5. Standard configuration

|

Serial Number |

Host standard configuration |

|

1 |

Spindle unit 8000rpm Volis or KENTORN or ROYAL brand |

|

2 |

Spindle servo motor: maximum speed of 8000rpm, power of 11/15Kw, torque of 52.5N m |

|

3 |

KND2100 |

|

4 |

Three axis feed motor: X/Y 18N. m, Z 27N. m, Z-direction with power-off brake (holding brake) |

|

5 |

The X, Y, and Z axes all use 45mm wide heavy-duty linear guides, and the X and Z axes have 6 sliders, all of which are HIWIN/PMI heavy-duty roller tracks |

|

6 |

Taiwan OKADA or Desu 24 disc type robotic arm knife storage |

|

7 |

HIWIN/PMI lead screw |

|

8 |

Moving hand pulse |

|

9 |

Centralized automatic oil lubrication |

|

10 |

Z-axis power-off brake system |

|

11 |

External cooling system and water tank |

|

12 |

air-cool |

|

13 |

Simple oil-water separation device |

|

14 |

Full protective sheet metal cover and guide rail cover |

|

15 |

Adjust the shim sleeve |

|

16 |

Tubular work light, warning light |

6、Select configuration

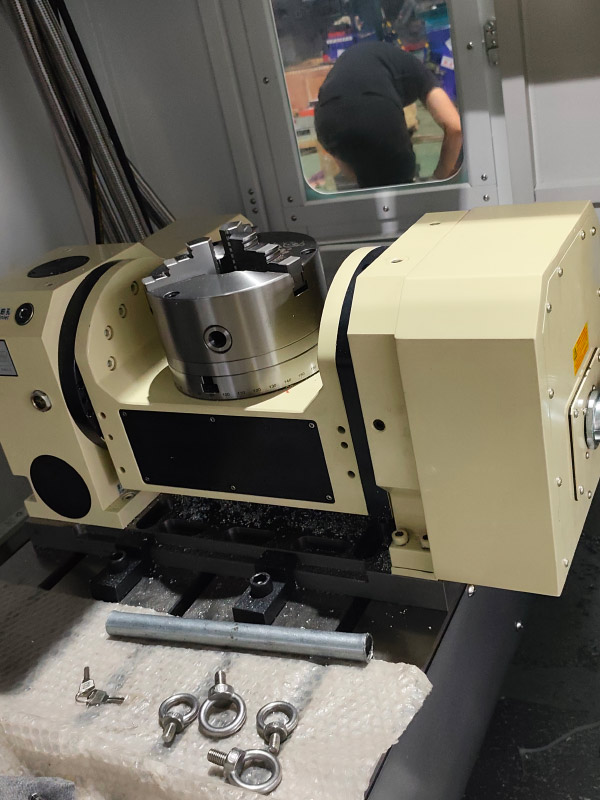

Optional Taiwan and domestic brand fourth and fifth rotation axes

Grating ruler (three-axis grating ruler detection system, three-axis grating ruler detection system)

The position detection of each coordinate of the machine tool adopts the German Heidelberg precision grating ruler, with a resolution of 0.1 μ m, to achieve closed-loop control of the machine tool and ensure the position accuracy of the machine tool. The grating ruler is sealed and protected.

Spindle internal cooling (spindle center outlet) system and high-pressure water pump

Spindle 10000/12000 RPM, spindle oil cooler

Explanation: Due to differences in configuration, special orders, CNC systems, and continuous improvement of products, some technical parameters may be affected. Please verify the actual situation when placing an order. We apologize for any inconvenience caused!